| Cat. No. |

CSFS-06 |

| Control unit |

Control panel |

8" Color touch-screen interface |

| Communication port |

Remote software control through Ethernet, up to 16 systems per PC |

| Data export through USB port |

| Analog AUX port for system extension |

| Program storage |

Up to 59,994 process programs |

| Log data storage |

Up to 100 process monitoring data files |

| Cabinet material |

ABS front panel and painted iron housing |

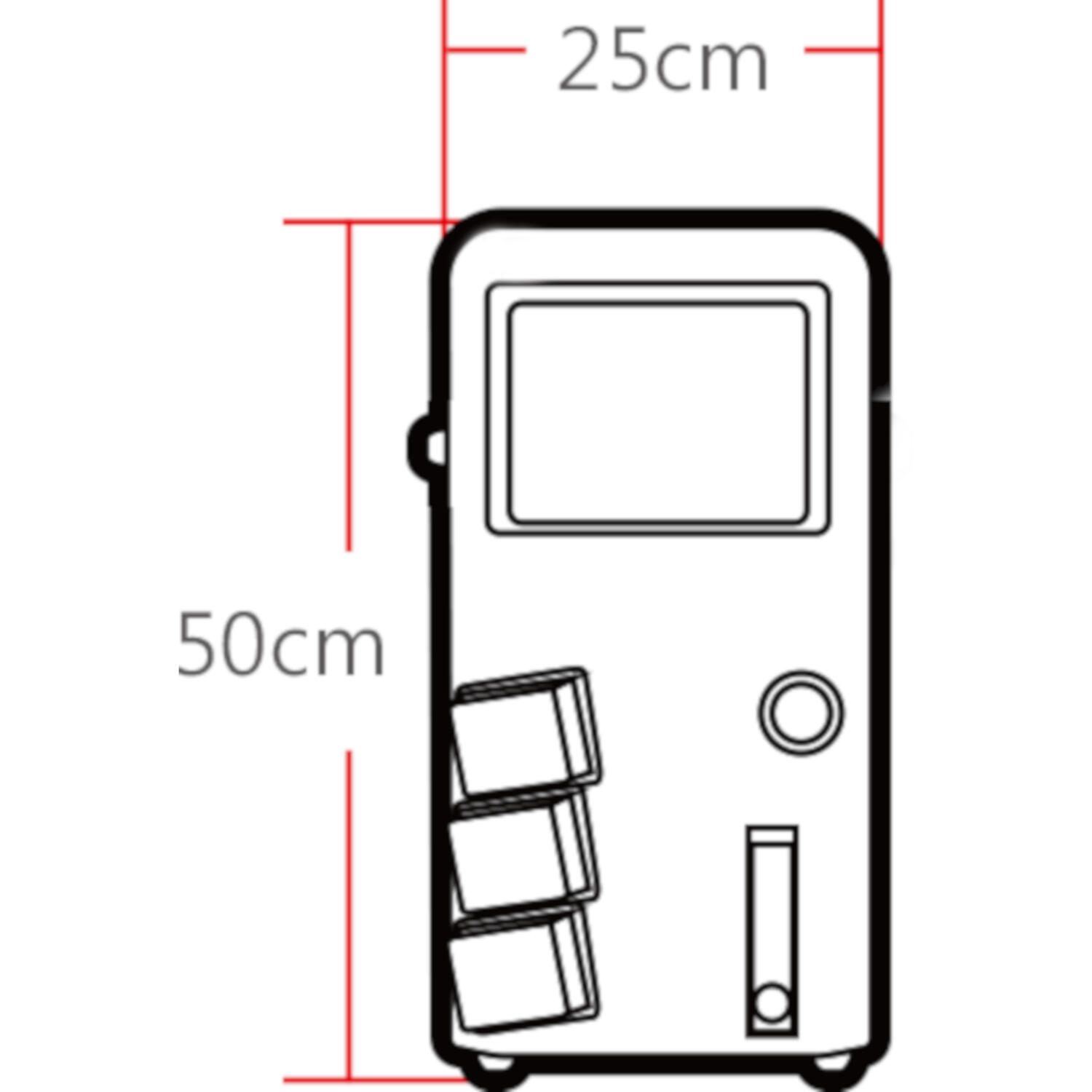

| Dimension |

Footprint: W x D = 9.84" x 20.08" (250mm x 510mm), Height: 19.69" (500mm) |

| Rated voltage |

110V~/220V; 50/60 Hz, 10A |

| Aeration |

Inlet gas flow-meter |

0,0.1-1LPM (0.5L), 0, 0.2-2.5LPM (1L), 0, 1-10LPM (3, 5L), 0, 2-25LPM (10L) |

| Sparger |

Orifice ring |

| Baffle |

Removable 316L stainless steel baffles |

| Temperature |

Heating |

1. Thermostat System: built-in heat exchanger (550W heater, water circulation pump) |

| 2. Dry heating system (heating blanket or heating base unit) |

| Cooling |

Cooling coil and solenoid valve |

| Range |

with FS-V-A / B / C series : 5°C (41°F) above coolant up to 60°C (140°F);

with FS-V-D series :5°C(41°F) above coolant up to 90°C (194°F) |

| Probe |

Platinum RTD probe (PT-100), non autoclavable |

| Control mode |

Manual or Programmable 15 steps PID control |

| Agitation |

Drive |

Removable top brushless motor |

| Speed range |

a. For extremely shear-sensitive cell line: 30 - 300rpm

b. For fermentation and cell culture: 30 - 1200rpm (0.5 - 5L) and 30 - 1000rpm (10L) |

| Resolution |

1 rpm increment |

| Impeller |

2 impellers for 0.5-1L vessel and double jacketed vessels

3 impellers for 3L vessel and above

Note: Customized impellers are available upon ordering |

| Control mode |

Manual or Programmable 15 steps PID control |

| pH |

Range |

2 - 14pH |

| Resolution |

0.01pH |

| Probe |

Gel-filled electrode, autoclavable |

| Control mode |

Manual/Acid start/programmable 15 steps PID control with adjustable deadband,

**pH stat with smart feeding technology |

| DO

|

Range |

0 - 200% |

| Resolution |

0.1% |

| Probe |

Polarographic DO sensor; autoclavable |

| Control mode

|

1-stage DO cascade response

a. Increase or decrease agitation speed

**b. Supply external oxygen source using solenoid valve switch (Oxygen enrichment module required, optional device)

**c. Adjusting DO level using accurate gas mixing control (Gas mixing station module required,

optional device)

**DO stat with smart feeding technology |

| ORP(optional) |

Measurement range |

-/ 2000mV |

| Resolution |

1mV |

| Probe |

Gel-filled electrode: autoclavable |

| Foam / Level |

Probe |

316L stainless steel protector with insulated PTFE tube, autoclavable, adjustable sensitivity control |

| Control Mode |

Foam: On/Off switch

Level: On/Off switch control with wet/dry probe set up |

| Peristaltic Pump |

Pump number |

3 x built-in Watson Marlow pumps, **1-2 external pump extendable (MU-D series required, optional) |

| Motor type |

Precise stepping motor; minimum speed is 1rpm |

| Speed range |

0 to 65rpm |

| Resolution |

1rpm |

| Control mode |

Manual or Programmable 15 steps feeding control; pump can be assigned for Acid, Base,

Antifoam and Substrate; **flow rate & total volume calculation |

| Exhaust |

Device type |

316L stainless steel condenser |